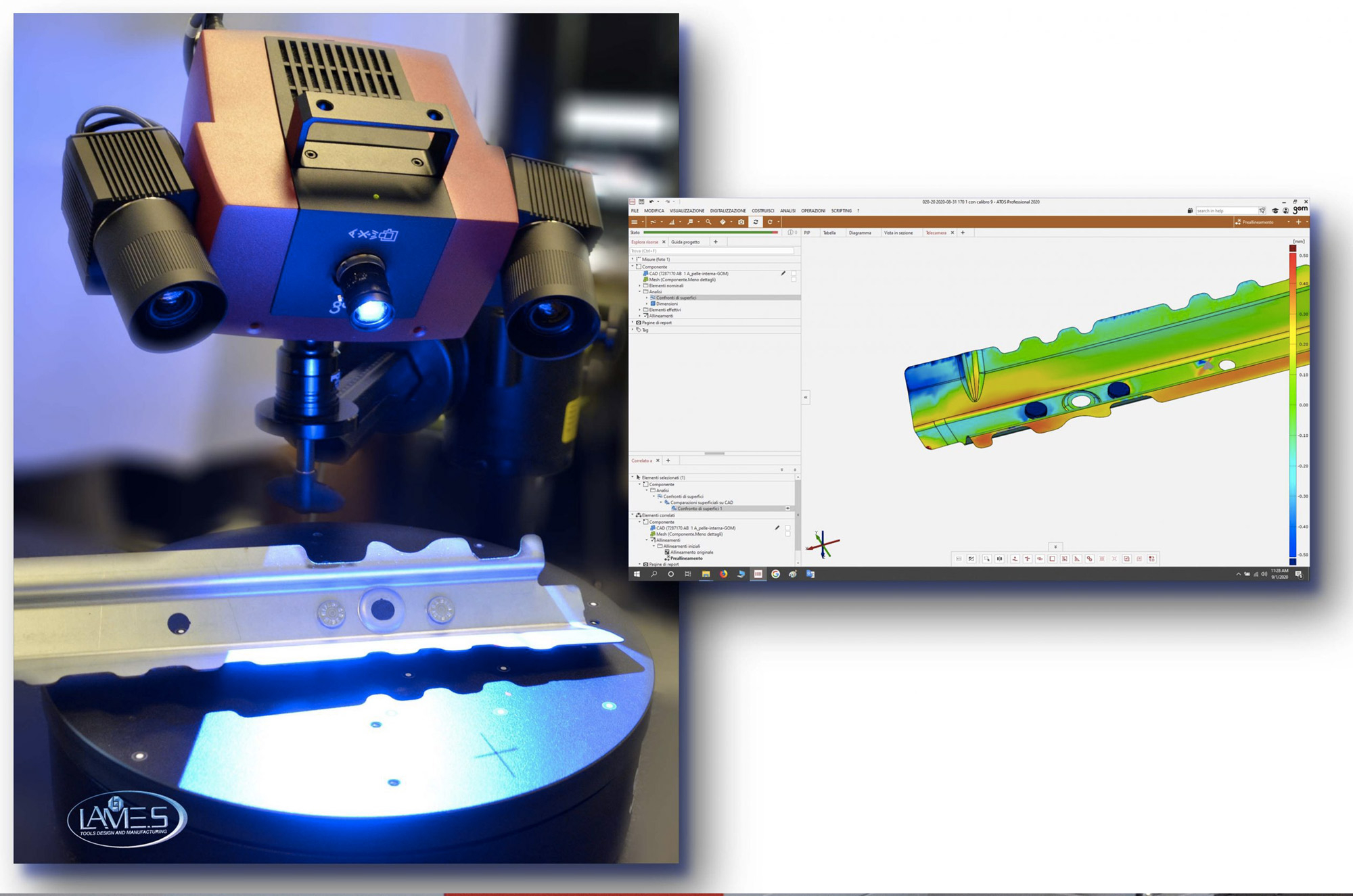

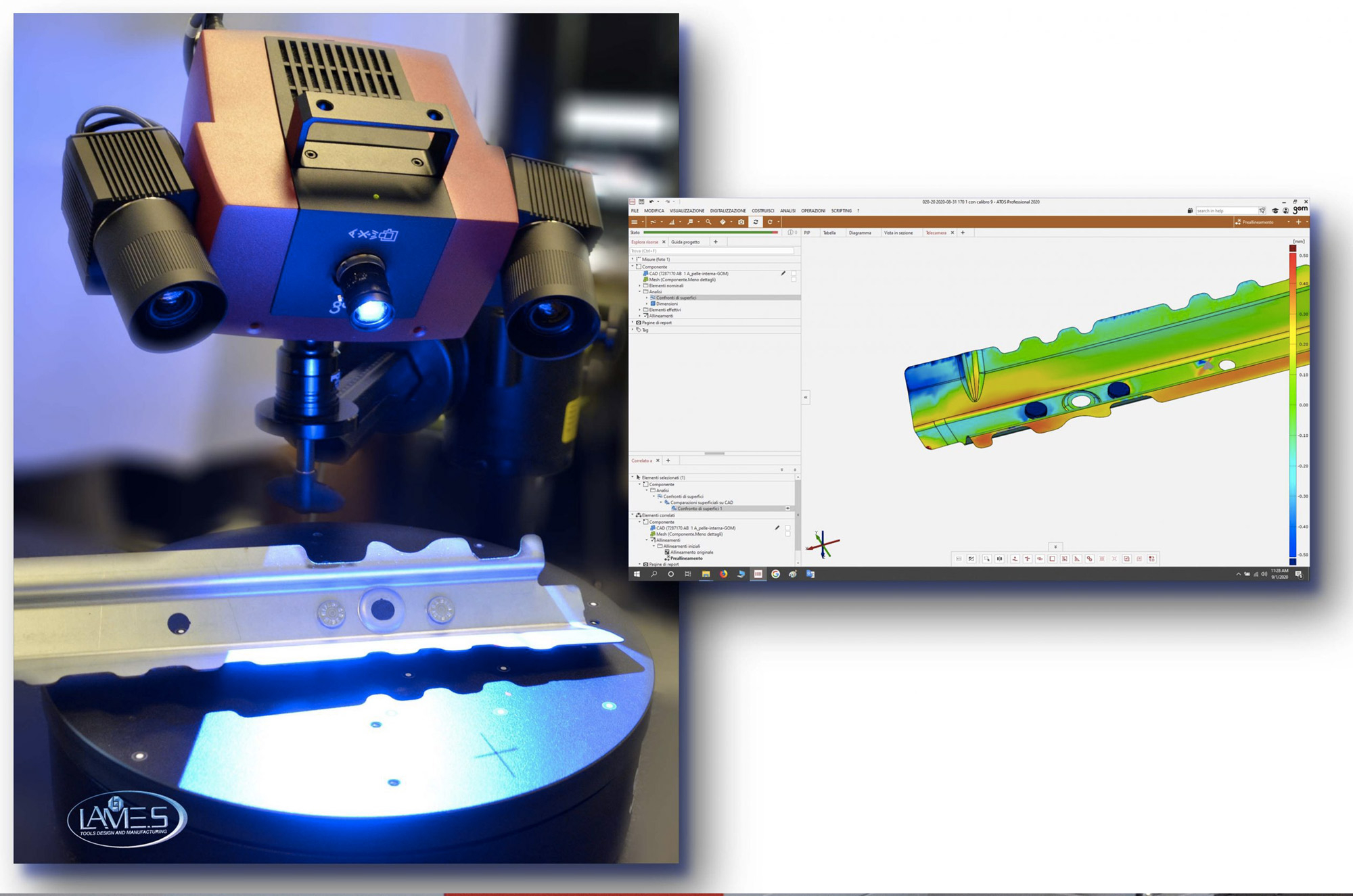

GOM

ATOS Compact Scan 8M

The ATOS series consists of industrial non-contact 3D scanners using structured blue light for measurements.

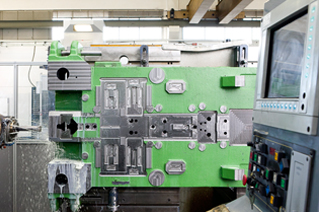

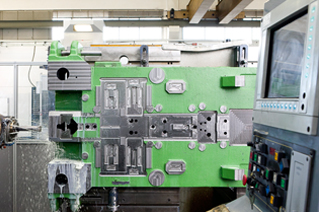

OKK HM800s

Horizontal machining center OKK HM800s.

Strokes:

X = 1040 mm

Y = 900 mm

Z = 880 mm

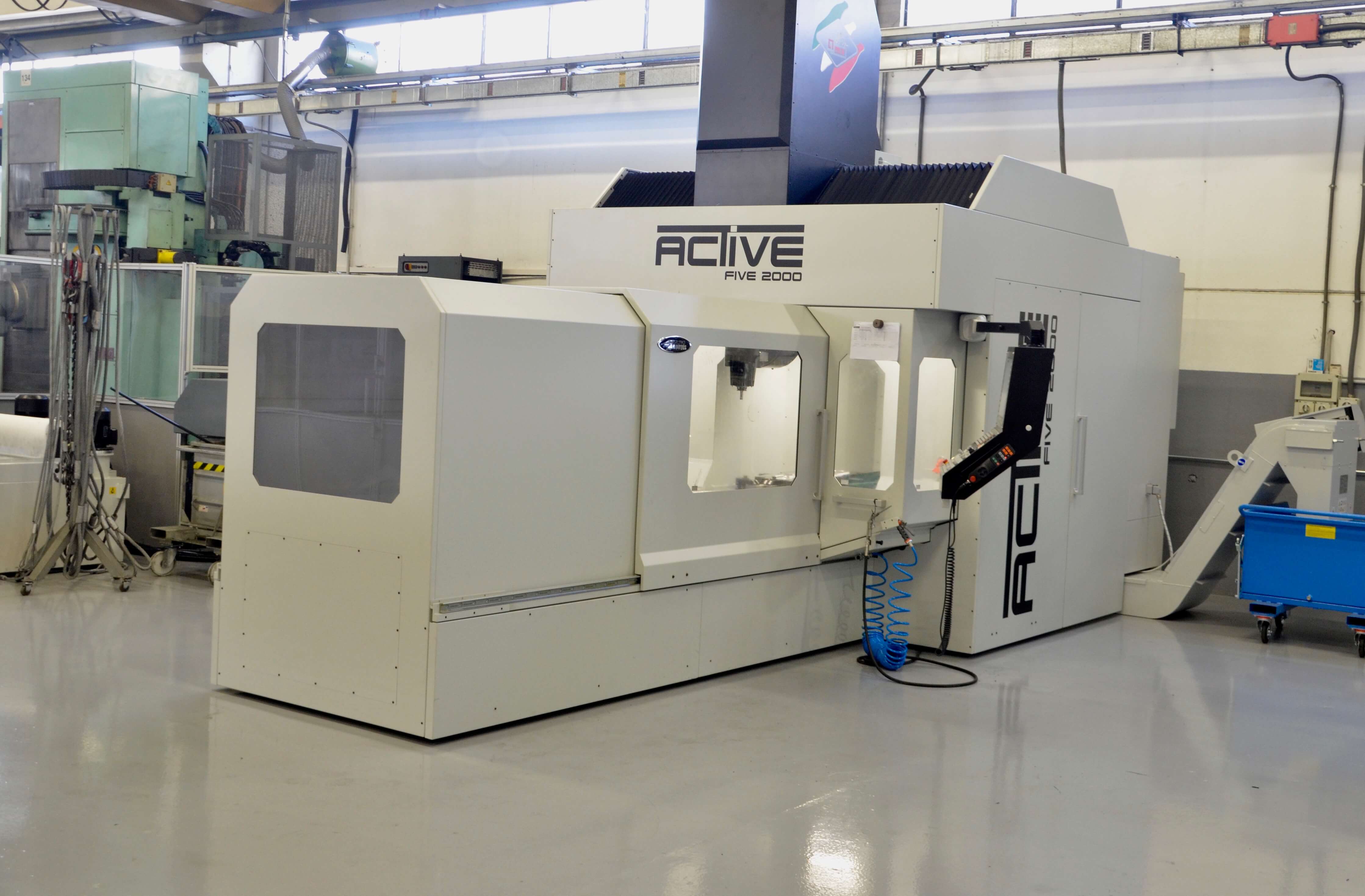

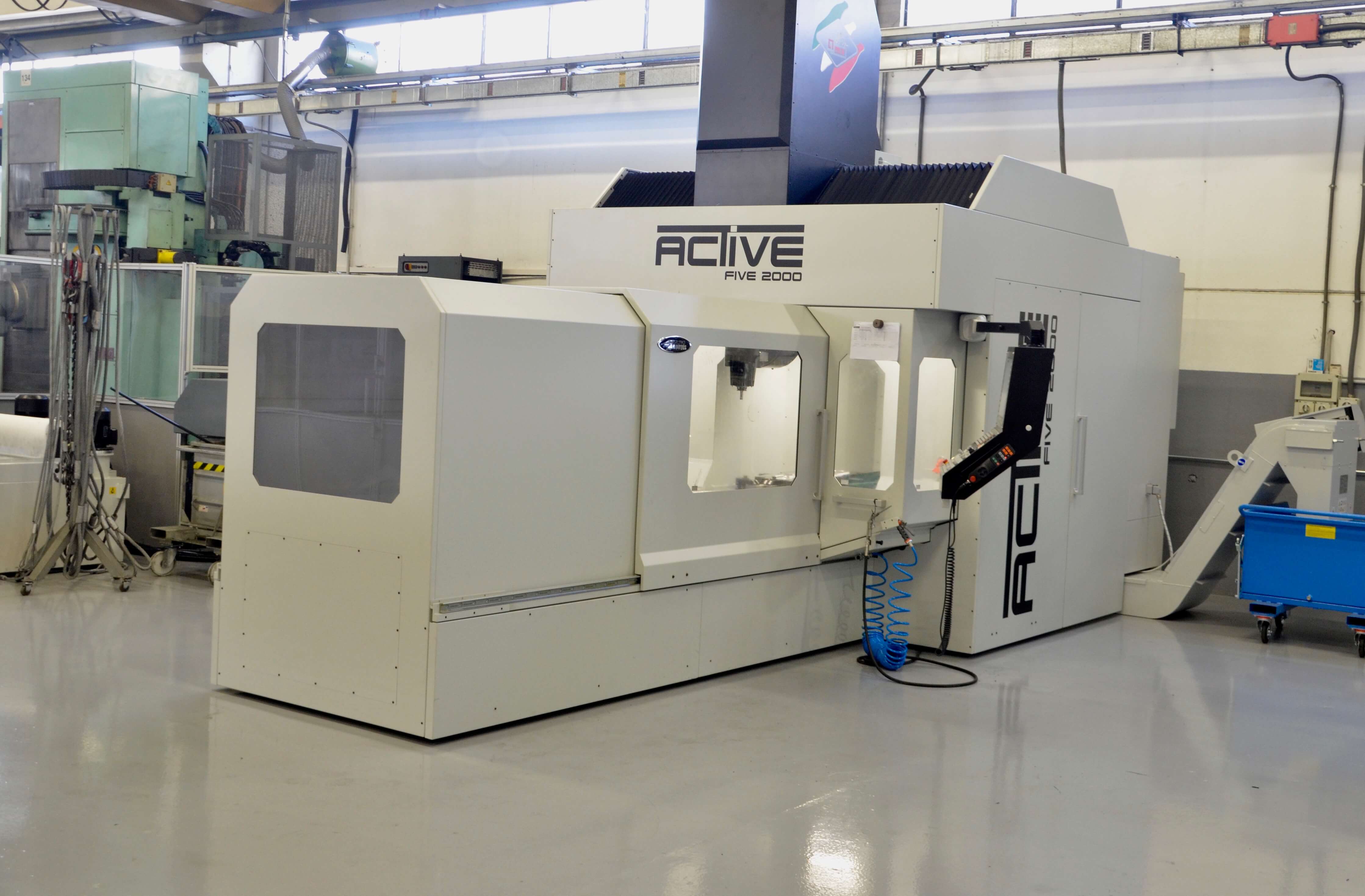

OMV Active Five 2000

The OMV Active Five 2000 is a high speed milling machine composed by a fixed gantry and a moving table.

Strokes:

X = 2000 mm

Y = 1800 mm

Z = 850 mm

Toolings no.: 120

OMV – Electra

The OMV-Electra is a high dynamic milling machine with moving column.

Strokes:

X = 6000 mm

Y = 1400 mm

Z = 2600 mm

FPT

The FTP is a milling machine with moving column and tooling change.

Strokes:

X = 4000 mm

Y = 1200 mm

Z = 2000 mm

THS

Fixed table Parpas THS.

Strokes:

X = 3000 mm

Y = 1200 mm

Z = 1500 mm

OKK

Horizontal machining center OKK HM600s.

Strokes:

X = 800 mm

Y = 750 mm

Z = 880 mm

Wire erosion machines

Automatic thread.

No.1 wire erosion, FANUC α1iE with automatic thread.

Working area:

– FANUC α C 600IA 600 x 400.

– FANUC α1iE 600 x 400.

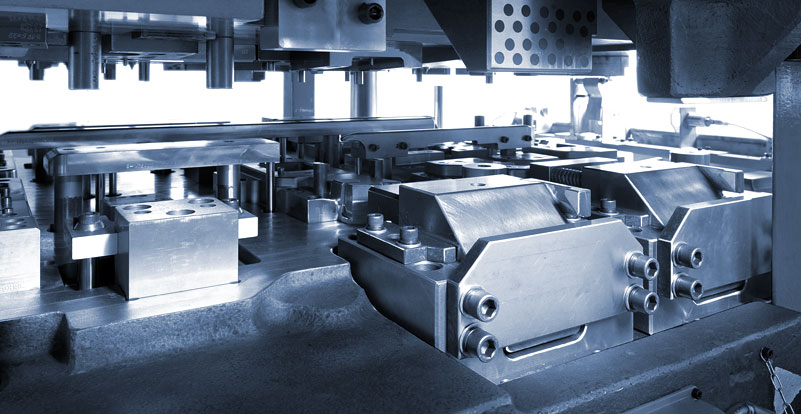

Müller press

Hydraulic press 800 to with hydraulic blankholder 400 to. Surface 4000 x 2200 (Müller)

Other presses

– Mechanical press 650 to with hydraulic blankholder 100 to, surface 3200 x 1700, feed “Iron 3 x 700”

– Hydraulic press 500 to, blankholder 250 to, surface 2000 x 1600

– Mechanical press 200 to